AndPlus acquired by expert technology adviser and managed service provider, Ensono. Read the full announcement

AndPlus acquired by expert technology adviser and managed service provider, Ensono. Read the full announcement

Project

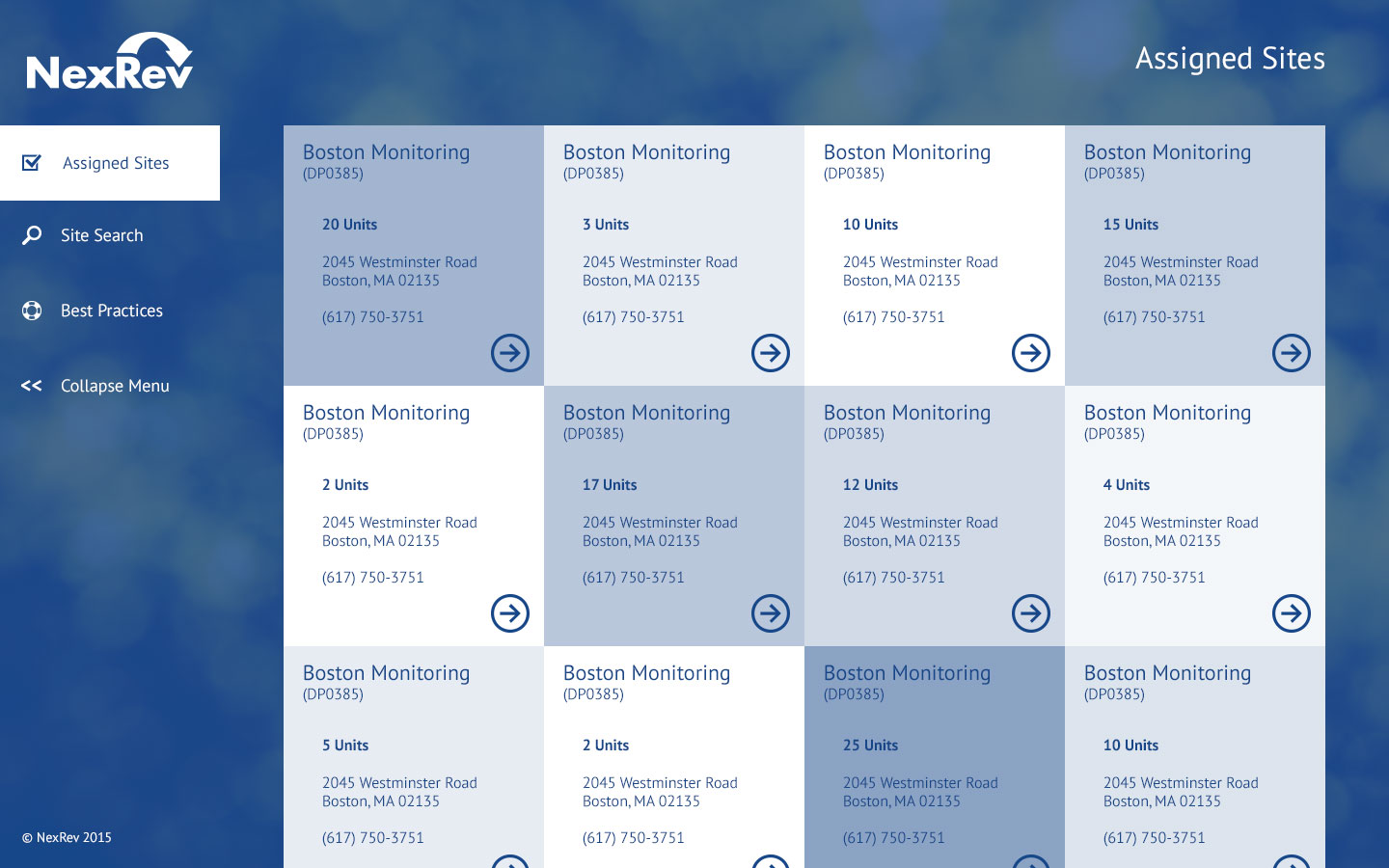

The NexRev DrivePak Configuration Tool (DCT) not only protects NexRev's reputation for excellence, but makes the process of installing variable frequency drives faster, more efficient, and with significantly fewer errors. The DCT combines an easy-to-use UI with powerful business logic and intelligent network communication all in one package.

The Product Vision

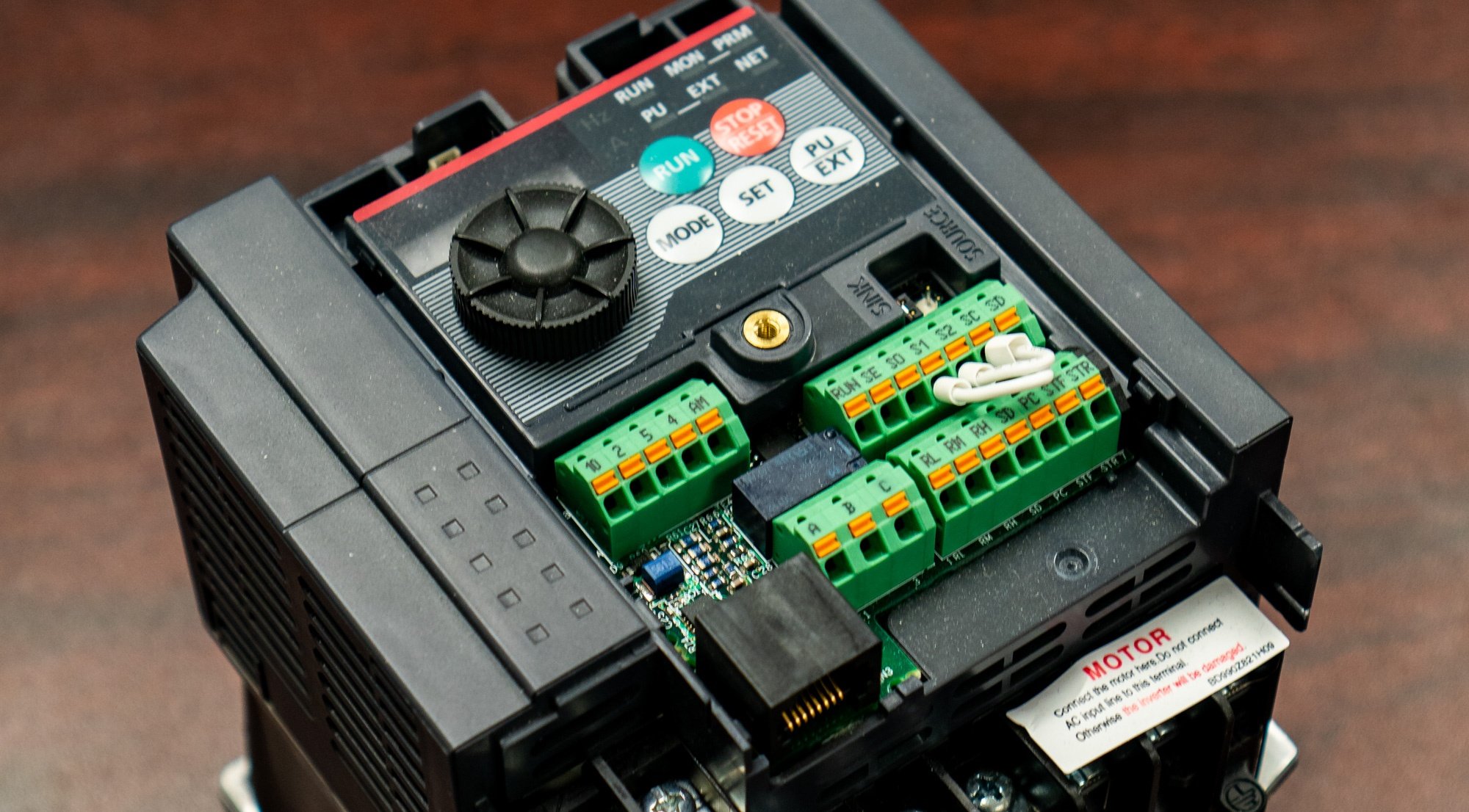

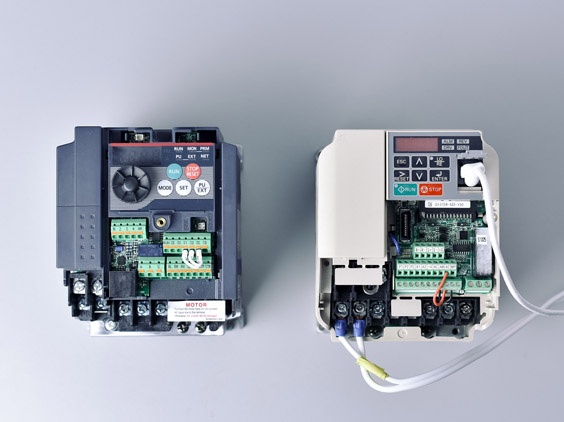

NexRev installs variable frequency drives (VFD) that are commonly used as aftermarket additions to commercial HVAC units. These VFDs allow the HVAC units to run at reduced power levels while still providing appropriate output to maintain a building temperature while saving power and money for large commercial building owners.

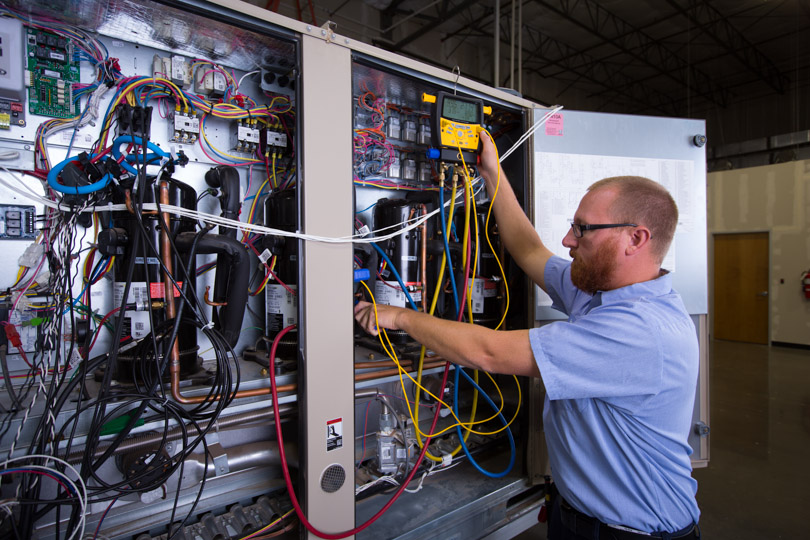

In order to expand their reach, NexRev engaged with dealer partners to install and program VFD units. In order to ensure that the VFD units were programmed with appropriate settings and done right the first time, NexRev needed to automate more of the process and provide quality control. They engaged with AndPlus to build a piece of software to do just that.

"All team members have been incredibly knowledgeable and display immense chemistry with each other. No one is afraid to speak up with ideas, and all work cohesively towards the best possible solution."

Project Manager, NexRev

The Challenge

AndPlus' first step was to build an MVP piece of software that simply took in manually-entered readings from various sensors on the unit and gave the installer tech input values for the unit. This basic, manual process showed that the complex algorithms used to program the VFDs could be translated easily into a simple-to-use piece of software.

The Solution

Once the initial hurdle of an MVP was cleared, the next phase was to add automatic intake of the sensor readings and an automated push to the VFD through a wired connection. Soon, the software would gather relevant data, crunch numbers, and program the drives automatically with little user interaction.

AndPlus also added the requirement for dealer partners to submit photos of the site to prove that the area was left clean and that the job was completed appropriately — even though dealer partners were doing the installation, NexRev's name was still "on the box."

or If you don't like forms, email us info@andplus.com

Read the AndPlus ratings and client references on Clutch - the leading data-driven, B2B research, ratings, and reviews firm.

257 Turnpike Road, Southborough, MA

508.425.7533

257 Turnpike Road, Southborough, MA

508.425.7533