IIoT is the Industrial Internet of Things: sensors and analytics devoted to monitoring, analyzing and managing industrial processes. It’s not limited to factories and transportation — think property and asset management, business process automation and more. It promises to be transformative, and the process of transformation has already begun: initially, we’ll see sharp improvements in the efficiency and reliability of structures and processes already in place, but within a decade we can expect to see industry operating primarily as an interlocking web of IIoT implementations.

In this post, we’ll look at the key areas of IIoT growth, the likely effects of increasing IIoT usage, and finally the primary business benefits of using IIoT.

Key areas in the growth of IIoT

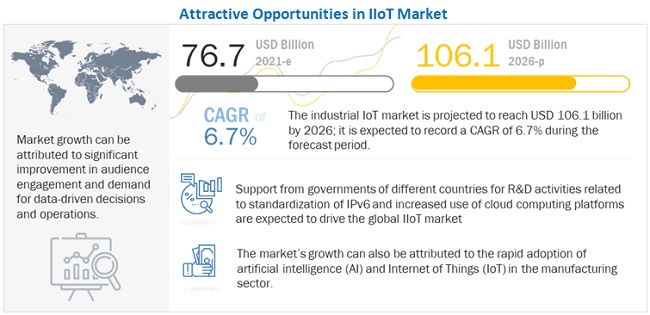

The Industrial Internet of Things is forecast to grow to over $106 billion by 2026, at a Compound Annual Growth Rate (CAGR) of 6.7%.

Connections between devices are forecast to grow to 37 billion by 2025. But this growth will happen first, and more strongly, in some sectors than others. In some sectors, IIoT applications are experimental; in others, they’re mature and productive.

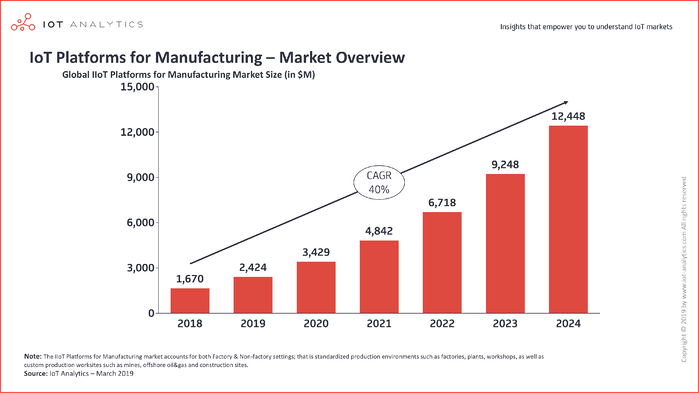

Manufacturing

Manufacturing is one of the first sectors to see the benefits of IIoT, allowing plants to suture together multiple processes, many of which have already been automated. The aim is to improve information flow across the manufacturing process, and, initially, automate basic decision-making about things like stock replenishment.

IIoT for manufacturing is growing significantly faster than the IIoT sector as a whole:

More strategic decision-making is driven by access to vastly-increased troves of operational data direct from sensor nets, too large and unstructured to be much use to humans in the raw. Machine learning tools can rapidly extract patterns from it, though, providing grounds for insights and strategic decision-making.

A good example of what this looks like on the ground is ABB.

ABB is a Swiss-Swedish multinational that mainly makes robots for other industrial applications. The company uses low-cost sensors to allow preemptive maintenance of its robots, as well as connected oil and gas production at its own facilities.

Beyond process visibility and maintenance, IIoT in manufacturing also allows for the creation of ‘digital twins’ — digital simulations of machines or processes, updated in real-time via sensors. These allow testing, trials and process simulation with accurate results without interrupting real production.

Utilities and ‘smart grids’

Utilities like water and electricity must deliver adequate supplies while both demand and supply constantly fluctuate. In peak times, grids struggle to deliver enough power; at 3 AM, there can be an oversupply, despite pricing and other policies intended to encourage night-time usage and reduce peak load.

This is made more difficult by manual decision-making with incomplete data and zero real-time visibility. The people who make choices about how to manage the resources of the grid don't know enough about what’s happening and the information they do have is out of date. IIoT can’t directly do much about supply, though in the future, we can expect generation to be integrated with distribution, especially as grids transition to non-fossil energy sources. It can help with management and feedback, though.

The global market in IIoT for energy is predicted to grow to $35.2 billion from its present $22.6 billion, an 11.8% CAGR. Increasingly, sensors are used at point of use and switching stations to balance load across the network dynamically, in real-time; this is likely to be especially fruitful in high energy consumption locations like manufacturing plants, as well as in densely-populated areas.

Home and work energy consumption devoted to heating buildings is a significant source of waste, and this loss is already being targeted by IIoT startups like Aquicore, whose sensor and analytics tools are designed to integrate with the solutions already deployed to commercial and residential buildings.

Logistics and transportation

Transportation and logistics is one of the best-developed spaces for IIoT implementation. Here, sensor and analytics setups are deployed to large-scale transportation businesses that can realize benefits in a modular way.

For instance, installing sensors in a warehouse can improve the efficiency of that warehouse. When sensors are installed in another warehouse, the two can be linked. When trucks are included, they realize their own analytics value and direct efficiency savings. There are synergistic benefits, but these can be attained gradually with shorter-term tactical improvements along the way.

In modern factories that use kanban stock level processes, it’s normal to use automated technologies like ECC or s4/HANA to manage actions that follow status changes. Yet, stock level status changes themselves are often done manually, with all the delays and human error this implies.

Automating the status changes via Auto-ID sensors integrates status changes with the rest of the stock management process, puts stock assessment and analysis on a real-time footing and eliminates the chance of human error.

In the long run, as driverless vehicles and robotic warehousing become coordinated with robotic manufacturing and the feedback from an increasingly digital purchase process, analytics from supply chain-wide sensor webs will allow both real-time reactions and strategic planning based on reliable data.

Healthcare and medicine

In 2019, the IIoT healthcare market was worth $60.8 billion; by 2027, it’s forecast to be worth $260.75 billion, a CAGR of 19.8%. Healthcare is both one of the fastest-growing spaces to work extensively with IIoT, and already one of the largest.

The reasons for early adoption are obvious: healthcare efficacy depends to a large extent on information gathering, storage and retrieval; much of that work is already done by machines; both accuracy and timeliness are important. The news that a patient’s blood pressure has changed might need to be with their clinician within a few minutes; accurate recording of less immanently-concerning tests are the basis of accurate diagnosis and treatment, as well as the evidence that no malpractice has occurred.

Medical practitioners increasingly rely on AI-assisted input from an array of sensors, including machines they were using before machine learning became available, to make diagnoses and carry out treatment. Healthcare administrators are using similar tools to allocate resources, plan budgets and structure processes.

The first section of the healthcare market to grow rapidly from IIoT is likely to be the medical devices field, with a forecast CAGR of 27.9% through 2027. This includes implantable and wearable devices such as pacemakers and orthopedic devices as well as regular-use devices like blood sugar tests.

Telemedicine, whose growth has been accelerated by the pandemic, will also benefit from IIoT implementation and grow rapidly. At the same time, healthcare is, like every other industry, at the end of a supply chain; it’s unique by virtue of its extreme specialization and precise tolerances, requiring exactly the right sterile equipment. This, together with the sector’s enthusiasm for sensor-equipped machine learning solutions to medical and administrative problems, makes it a candidate for rapid growth.

Industrial building controls

Power, HVAC, building and environmental integrity (such as water, fire risk, and air quality) are all key opportunities for IIoT implementation in buildings and in construction sites.

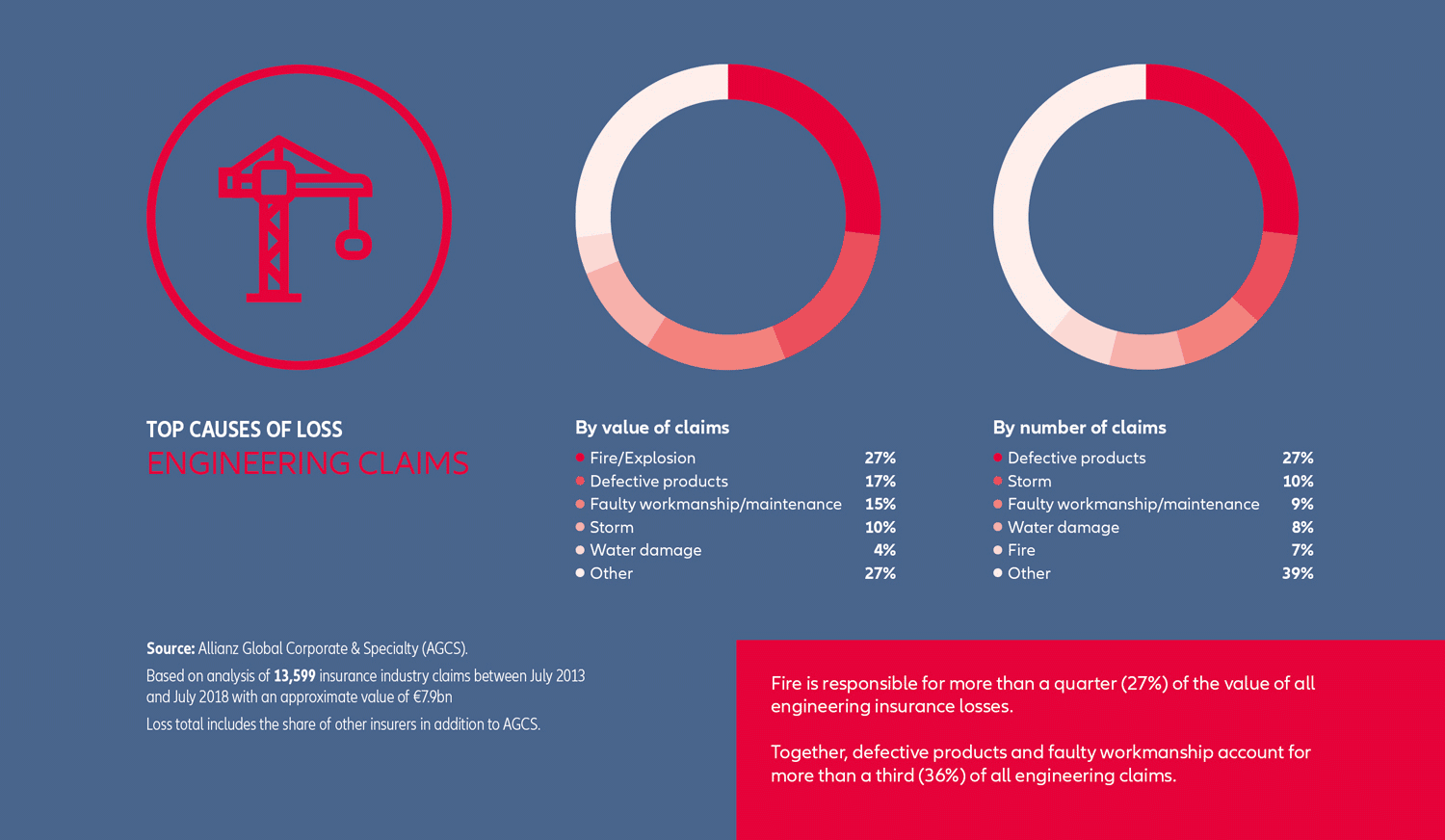

Construction site fires have caused $2.44 billion in losses over a five-year period; while these losses are largely borne by insurers, changes in the insurance industry, themselves technology-driven, mean there’s a strong incentive to reduce the damage.

At the opposite end of the scale from construction-site fires, extant buildings leak money through ill-configured HVAC (Heating, Ventilation, Air Conditioning) systems. With centralized control and poor access to real-time data, these systems are often at odds with the needs of the building’s users and consume energy inefficiently.

A common solution to this problem is Variable Frequency Drives, an aftermarket solution allowing HVAC tools to run at reduced power output while maintaining acceptable building temperatures. However, these VFDs are often installed by third-party installation crews and can be incorrectly configured; solutions include a sensor-informed automated configuration tool such as the one we developed for NexRev.

What problems is IIoT solving?

IIoT lets businesses that already have globally dominant positions in production and manufacturing retain those positions. For businesses like Bosch, it enables them to offer additional value to their customers — such as the company’s Track and Trace program, which allows workers to find tools quickly and easily by adding sensors to them. This simple use of tool-based sensors saves hours of ‘where’s my drill’ time, but it’s since been expanded to supply chain and manufacturing elements and is growing as its underlying ML algorithm becomes more effective.

Smaller businesses, startups, and newer or less well-positioned business units of established enterprises can all benefit from offering an innovative — even potentially disruptive — solution. When you can’t compete on size and scale and you don’t already have a client base, this approach makes sense, offering a path to growth and market leadership.

This is true in businesses with an entirely new offering or idea, but it’s also true in relatively ‘stagnant’ industries where improved economies of scale, economy or method were regarded as impossible. In many cases, such industries or business units within larger companies are no longer regarded as profit centers; IIoT efficiency and integration effects can make them so again, increasing domestic and international competitiveness.

What are the key IIoT business benefits?

IIoT brings to modern industry what the first industrial revolution brought to an economy based mainly on handicrafts and agriculture: economies, process efficiencies, accurate resource management, record-keeping, specialization and profitability.

Process efficiency

IIoT improves process efficiency by reducing the requirement for human intervention. While there are some tasks at which humans excel machines, data entry and item tracking are definitely improved by eliminating as much manual intervention as possible.

Optimal uptime

Equipment failure and malfunctions account for 42% of unplanned downtime in manufacturing. As IIoT implementations shift focus from reactive to predictive maintenance, unplanned downtime falls — as does wasted maintenance.

Increased production throughput

IIoT can increase manufacturing throughput by ensuring stock, managing production processes, and integrating with warehousing and transportation. Throughput rises as delays, bottlenecks and shortages fall.

Increased awareness and control of the manufacturing process

Mines dig up ore, refineries turn it into metal, foundries turn it into billets, mills turn it into parts. Where along this line does the process of making a car door actually begin? Manufacturing begins far before parts are bolted together — and in the case of steel, 85% of which is reclaimed from scrap, it continues long after the vehicle is sold. As governments turn their attention to a ‘circular economy,’ IIoT can help businesses track, analyze, predict and control increasingly-circular manufacturing processes for efficiency, profitability, and regulatory compliance.

Experience innovation

Users and stakeholders care more about their experience than what goes on under the hood. Innovative experiences are far more important, from a business perspective, than innovative products or features. IIoT allows manufacturing, logistics, delivery and other industrial sectors to offer new, better, more enjoyable and desirable experiences to their customers. But this also extends to other stakeholders: partners, suppliers, users and workers can all be offered a new, better journey to a new, improved outcome.

Takeaways

- IIoT is already a multibillion-dollar industry in its own right, forecast to grow at many times the rate of Wall Street, the economy or any other industrial sector

- Initially, gains will primarily be in efficiency and accuracy of existing processes

- As IIoT becomes more ubiquitous and influential, it will change industrial practices in its own image and eventually transform how industry operates

- The future of industry will be integrated, automated, and managed by automated short-term decision-making based on webs of sensors collecting and transmitting data to software before presentation to humans